What is Continuous Improvement?

To remain relevant in today’s market, organisations need to have processes and strategies in place to ensure that they stay in touch with the needs of their stakeholders and customers. Continual improvement is the process of increasing quality and services through incremental gains. This, in turn, allows organisations to benefit from long-term advancements over short-term gains.

Gradual

Gradual changes usually go unnoticed until reflection on how far an organisation has travelled over a particular period of time.

Incremental

Incremental improvements consist of an improved parameter implemented at a given date to a pre-decided period and further improvement based on the same parameter after proper analysis of results of consistency. It is made up of a series of incremental changes.

Breakthroughs

Breakthroughs are improvements defined by one giant leap – also known as a step change. The method of achievement is the same, but breakthroughs tend to arise out of chance discoveries and can take years before being made. These are considered the disrupters – those that change the current direction of a product, service or business. Businesses must be careful that the steep rise without periodical analysis – and lack of study of the effect on other elements of a Quality Management System like objectives, policies and complaints – could be detrimental and counterintuitive to the overall improvement plan.

Benefits of Continuous Improvement

The benefits of continuous improvement are wide and varied. Firstly, employing the ideas for improving processes in the organisation that the team has created makes the new methods practical and believable to employees. Secondly, once employees see their ideas being implemented, they will be more inclined to find new ways to improve other processes. Employees feel empowered by the new approach. This will reinforce their commitment through better teamwork and higher motivational levels. Overall, this all leads to greater productivity and a happier work environment. Finally, implementing continuous improvement will reduce efficiency waste and encourage more ‘small wins’ by doing less. This leads to lower costs and higher quality outcomes and improves organisational performance.

Which continuous improvement tool to use depends on the organisation’s context. As each organisation is unique, so will need to be constant improvement tools used. At Southpac, we teach a variety of tools to our participants. These include analysis, improvement measures, charts, diagrams, root-cause analysis, and higher-level transformational projects such as Kaizen events.

The Continuous Improvement Cycle

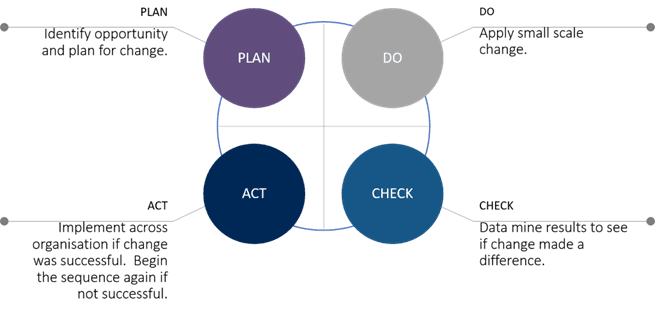

The diagram explains how ‘small wins’ are continually achieved in the organisation. The following steps in the continual improvement cycle are simple to implement. However, they are comprehensive in identifying and formulating action plans.

Top 6 Benefits Of

Continuous Improvement

Which industries should be implementing Continual Improvement?

All industries would benefit from implementing continual improvement tools. However, there are specific industries that Southpac International has worked with to deliver visible results.

From mining, manufacturing, and construction to retail and services, Southpac clients now have systems in place that will enhance and sustain continual improvement. These systems make teamwork, learning and innovation a positive and rewarding part of their organisations. These companies employ continual improvement tools to collectively nurture a culture of collaboration, innovation and sharing among employees and management.

Continuous Improvement In The Workplace

Continuous improvement is usually considered a good thing. However, when continuous improvement in one area negatively impacts another, it may not be so good. To ensure that we are always moving forward, consideration must be given to all areas of the organisation, including the environment that it operates within. This will ensure that change in one area does not negatively impact another. This is proper systems thinking.

Most of us face all kinds of improvement programs in our daily work, specifically to improve the parts. We tend to focus on improving the metrics in one area without consideration for another. It is as if those metrics are the most important in our work, but even more ignorant is focusing on them separately rather than thinking about the effects on the system as a whole. Finding deficiencies and getting rid of them is not continuous improvement. Determine what you want, not what you don’t want.

Southpac International’s Systems for Continual Improvement Course

Our course on Systems for Continual Improvement encapsulates the most progressive and innovative thinking in continuous improvement theories and methods. To remain current and fresh in this competitive market, businesses must encourage their stakeholders and employees to invest their time and ideas into planning, acting, engaging, and reporting on what systems work for each company requirement.

Our course will not teach you just the root-cause analysis program or even an understanding of why campaigns or programs haven’t worked out how they were imagined. Southpac International addresses proactive change by addressing the crux of the crucial events in the organisation and dovetailing these in dedicated programs.